Last weekend we finally got the plastic on the hoop house, just in time too, before the first big snowstorm.

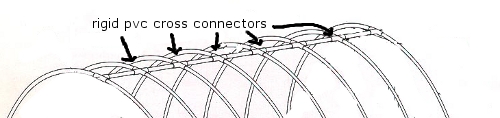

A couple of days after the storm something did not look right. Several of the “ribs” were no longer bent. A quick inspection revealed that the snow that had accumulated against the bottom had pressed against the ribs, making them bend in more, tightening the arch. This had put too much force on the pvc cross connectors on top, and several of these had broken.

The house still stood by virtue of the connectors still in place, the plastic covering (which did not tear even at those point where the loose ribs were poking into it), and the milder weather. Yesterday DH and I had a chance to go out and fix it.

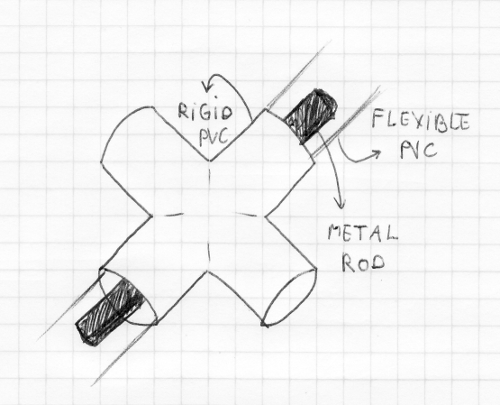

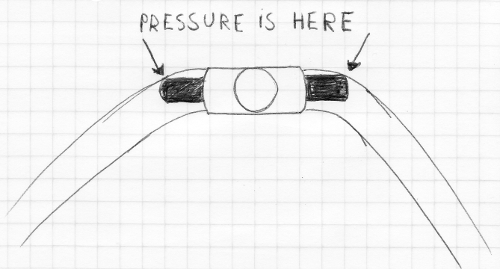

The cross connectors can’t stand up to that kind of pressure because they are made of rigid pvc, which may get brittle in the freezing temperatures. Not being able to bend, they just break. So we reinforced each connector with a metal rod. The pressure of the arch is now on the metal rod inside the joint and on the much more bendable pvc of the ribs where the rod’s endpoints press on them.

Hopefully this will do the trick, but to prevent the pressure from building in the first place, we are also creating a cross brace on the most vulnerable side of the hoop house. This will at least give us some extra time to clear away the snow. (More on this later.)

I peeked underneath the row covers and everything is doing well, though the Russian kale looked a bit peekish – next year I will be following the Matron of Husbandry’s tips on winter hardy veggies. I also had the chance to harvest some of our first winter harvest:

Swiss chard, harvested mid-December. So good!

I still have carrots but I can’t pull them up now that the bed is frozen solid. Maybe tomorrow at mid-day? It’s supposed to get near 50’F.

Very interesting. I always say the best way to learn is by doing. I’ve been interested in a hoop house ever since I saw yours. Your experience will be very helpful to others of us. Swiss chard looks absolutely yummy!

The hoop house is an interesting experiment, interesting also as a collaboration between myself and DH, and we don’t always agree on its design. The door, for instance… we’ve tried one door system (it lasted all of half an hour in the rain), and are now pondering a replacement. Will update on that when I come back.

My expirence is not to use any connectors on the pvc hoop, The joint always fails. best to use a 20 foot length entire. I use 1″ electrical grade PVC for the hoops and 2″ pvc for the ridge pole. The 2″ is stiff enough to keep a nice straight top. I tape the ridge to the hoops with Gorilla tape or reinforce with rebar wire between two layers of Gorilla tape.

hey, did adding that metal rod add enough support for your hoop house? i live in zone 3A (we get a lot of snow) and was thinking of making a hoop house of my own.

Hi Matthew,

It didn’t help.

As Martin suggested, the pvc isn’t strong enough to hold snow weight. We switched to metal conduit. You can read about that here: http://blog.bolandbol.com/2011/05/31/a-barn-hoop-house-raising-part-2/

I should write about that too: try to get the hoop in one conduit. We didn’t and soon the hoops unbent to such a state that they bent also the connector, threatening to tear the fabric.

My advice: don’t cut corners. You’ll invest in something that won’t work long. Better wait, save up, and buy the good stuff.